In the last few years in-line particle size analysis has continued to reach more and more importance since this information is required for control and optimisation of chemical processes. Since a few years OPUS based on Ultrasonic Extinction is applied for in-line particle size analysis. As primary measurement information the frequency dependent Ultrasonic Extinction which can be converted by a mathematical algorithm into a particle size distribution, is used. Based on Ultrasonic Extinction very robust sensors can be built, which also can cope with typical process pressures and temperatures. The use of Ultrasonic Extinction offers a variety of advantages compared to optical principles. The analysis can be carried out in opaque suspensions at high concentrations (typically up to 70% by volume.) The measured particle size distributions are only affected very little by the concentration, which may vary across a wide range. Contamination on the sensor components does not influence the results.

Using Ultrasonic Extinction the complete volume in the measuring zone is analysed so that the information about the suspension is gathered from the volume and not only from a small layer in front of a glass window as with optical instruments. Ultrasonic extinction is dependant on the acoustic properties of the product to be analysed. The acoustic properties can be determined by measurement quite easily and with high accuracy. Nevertheless the product must be known quite well regarding its consistency before particle size analysis can be performed.

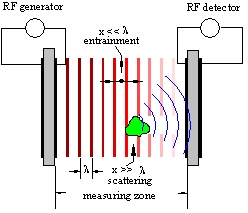

Principle of Ultrasonic ExtinctionThe design of an instrument for the determination of the frequency dependent Ultrasonic Extinction is schematically presented in figure 1. An electrical high frequency generator is connected to a piezoelectric ultrasonic transducer. The generated ultrasonic waves are coupled into the suspension and interact with the suspended particles. After passing the measuring zone the ultrasonic waves are received by an ultrasonic detector and converted into an electrical signal. The extinction of the ultrasonic waves is calculated from the ratio of the signal amplitudes on the generator and detector side. |

Figure 1 |

The instrument is designed as a finger probe and can be adapted to nearly all kinds of process pipes or vessels using a DN 100 flange. OPUS is prepared for fully automated real-time particle size analysis in process environments (Temperature 0 - 120°C, Pressure 0 - 40 bar, pH-value 1 - 14). As an option OPUS is available in an explosion proof version as well (Zone 1 ambient, Zone 0 in the measuring zone). Since OPUS is available in different length from 330 to 3500mm (measured from flange to tip) the instrument can be applied to a variety of processes.

For smaller pipe diameters adapters covering process pipes down to DN10 are available. Using an automatic cleaning system the probe can be moved out of the process pipe or vessel for cleaning, inspection or maintenance without the need to shut down the process. OPUS has been applied successfully to different kind of industrial processes

|

Ultrasonic Extinction |

| Overview |

| OPUS |

|

Software |

| WINDOX 5 |

| KSIGMA |

|

Accessories |

| Computer |

|

Information |

| Publications |

| Applications |